SeccoMix R with DiamondFace for the agitators of mobile vessels

Sealing the agitator shaft of a mobile vessel is a very special task when dealing with a process in vaccine production. Liquid lubricated seals offer the best conditions for this application. However, the operation of the dry running seal DF-SeccoMix R from EagleBurgmann is more convenient and just as reliable as it is safe.

Operating conditions: d = 35 mm (1,37“), p = 3 barg (43,5 PSIG), t = 40 °C (104 °F), vg = 1,5 m/s (5 ft/s)

Read on for the entire case study

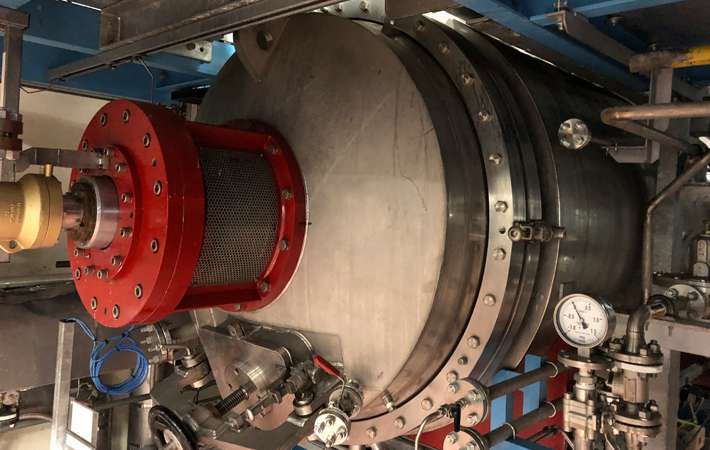

Retrofit of agitators with AGSZ seals

When the process medium in the production of metformin may not be contaminated with sealing medium under any circumstances, gas-lubricated seals for agitator shafts are the first choice. The Norwegian company Vistin Pharma took a daring step away from oil-lubricated to nitrogen overlayed AGSZ seals from EagleBurgmann.

Operating conditions: d1 = 125 … 140 mm (4,92“ … 5,51“), p1 = Vacuum … 2,5 bar (36,3 PSIG), t = 110 °C … 145 °C (230 °F … 293 °F), vg = 0.3 … 0,6 m/s (0,98 … 1,97 ft/s), n = 50 … 90 min-1

Read on for the entire case study

HSMR double seal for foam breakers of a pharmaceutical company

In the highly sensitive production of vaccines, only a few barrier media and materials are approved for mechanical seals. If steam condensate is to lubricate silicon carbide sealing surfaces, premature wear is inevitable. How it actually works with the double seal HSMR from EagleBurgmann is demonstrated by the case of an internationally operating pharmaceutical company.

Operating conditions: d1 = 40 mm (1.57"), p1 = Vacuum ... 1 bar, t = 4 °C … 128 °C (39.2 °F … 271.4 °F), n = 1,500 min-1

Read on for the entire case study

Dry-running agitator seal SeccoMixR in paddle dryers

A pharmaceutical company converted liquid-lubricated mechanical seals in paddle dryers to dry-running double seals SeccoMix R from EagleBurgmann. They proved to be a reliable alternative, especially for moderate operating conditions

Operating conditions: d = 200 mm (7,87“), t = - 20 °C … + 90 °C (68 °F … 194 °F), vg = 0.1 m/s (0.32 ft/s)

MR-D double seal with DiamondFace in bioculture production

Poor lubrication and sliding faces in hard-hard pairing - there are better conditions for the perfect functioning of a seal. Liquid-lubricated MR-D with DiamondFace nevertheless reliably seals the agitator of a fermenter for the production of biocultures for the long term.

Operating conditions: t = 37 °C (99 °F), p1 max. = 1 bar (15 PSIG), p3 max. = 3 barg (44 PSIG), n max. = 700 min-1, Barrier medium: Steam condensate

Single seal Cartex-SN with DiamondFace for high pressure centrifugal pumps

Constantly changing operating conditions place extreme demands on pump seals in the production of antibiotic active ingredients. DiamondFace technology significantly extends the life of Cartex-seals and enables the reduction of stock costs through rationalization.

Operating conditions: t = usually ambient, p1 max. = 1 barg (14.5 PSIG), n max. = 1,450 min-1