EagleBurgmann International

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

EagleBurgmann WELTWEIT

Mit rund 250 Standorten und 90 Servicecentern, sind wir in den bedeutenden Wirtschaftsregionen vertreten. Die Vorteile liegen klar auf der Hand: kurze Wege zu unseren Kunden, schnelle Reaktionszeiten und die gleiche Sprache.

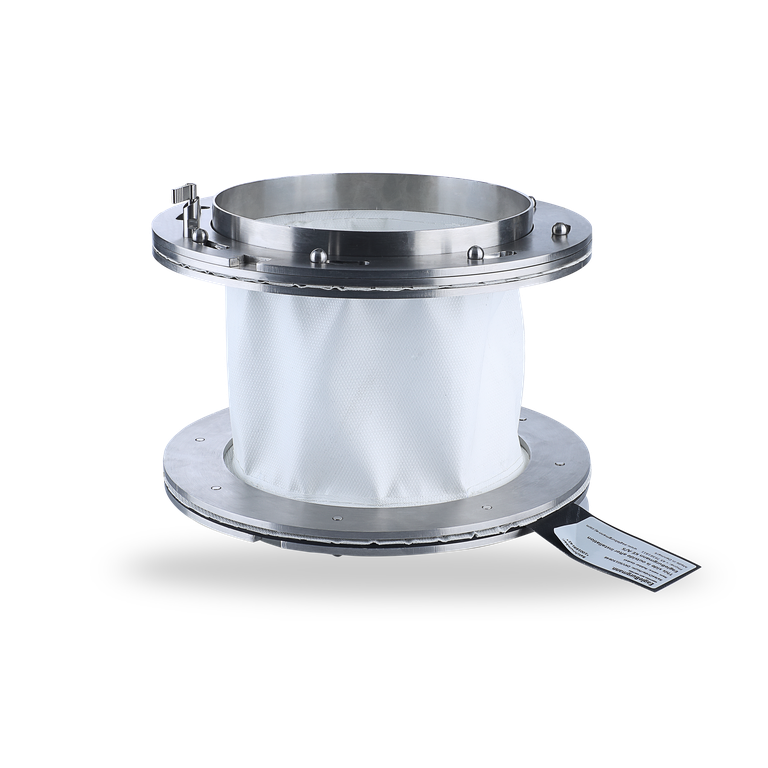

Fabric expansion joints

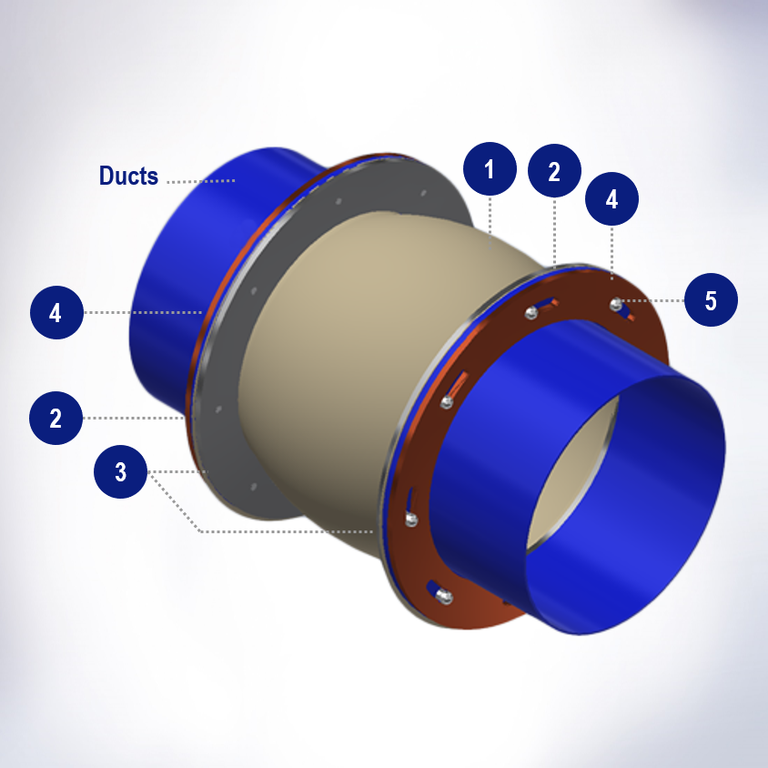

Plug & Run Expansion joints

| Item | Description |

| 1 | Fabric expansion joint |

| 2 | Duct flange |

| 3 | Backing flange |

| 4 | Locking flange |

| 5 | Locking bob |

Plug & Run Expansion joints

Merkmale

- Fabric expansion joint (FEJ) with quick lock system

- Next generation of patented flange design

- Available in hygienic-friendly design according to EC 1935/2004, EN 10/2011, FDA

- Reduction of downtimes

- Suitable for standardization

Vorteile

- Approved plastic and rubber materials

- Leak-proof design up to 2 bar (pressure shock tested)

- Hygienic-friendly design with minimized creases and no crevices

- Resistant to cleaning fluids

Einsatzbereich

Temperature: -35 ... +260 °C (-31 ... +500 °F)

Pressure: -0,05 ... +0,2 bar (-0.72 ... +2.9 °F)

Axial compression: 65 mm (2.55")

Lateral movement: 25 / 26 mm (0.98 / 1.02")

Standards und Freigaben

Fabric material with hygienic certificate according to EU regulation EC 1935/2004, EC 10/2011, FDA

Empfohlene Anwendungen

- Food processing

- Pharmaceutical

- Chemical industry

- Industries with higher requirements

Funktionsbeschreibung

- For applications in which fabric expansion joints are changed permanently from one connection to another

- In places where fast FEJ exchange is needed at any time

- As plant standard for higher efficiency

Ähnliche Produkte

Acouseal expansion joint

- Single layer design

- Designed for acoustic demanding environment in GT inlets

- Absorbs movements and vibrations in multiple directions

- 100 % gas tight connection

- Excellent and proven sound reducing properties

Combine-X expansion joints

- Multi layer design

- Compensates for movements in several directions simultaneously

- Excellent form stability

- Can be delivered as fabric only or as preassembled unit

- Custom made to fit actual working conditions

- Specifically designed for gas turbine systems

Flexgen expansion joints

- Multi layer design (Flexgen 2002: single layer construction)

- Compensates for movements in several directions simultaneously

- Can be delivered as fabric only or as preassembled unit

- For dry condition

- Custom made to fit actual working conditions

Kontakt

Individuelle Lösung anfragen

Wir entwickeln und produzieren kundenspezifische Sonder- und Einzellösungen für jeden Anwendungsfall.