EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

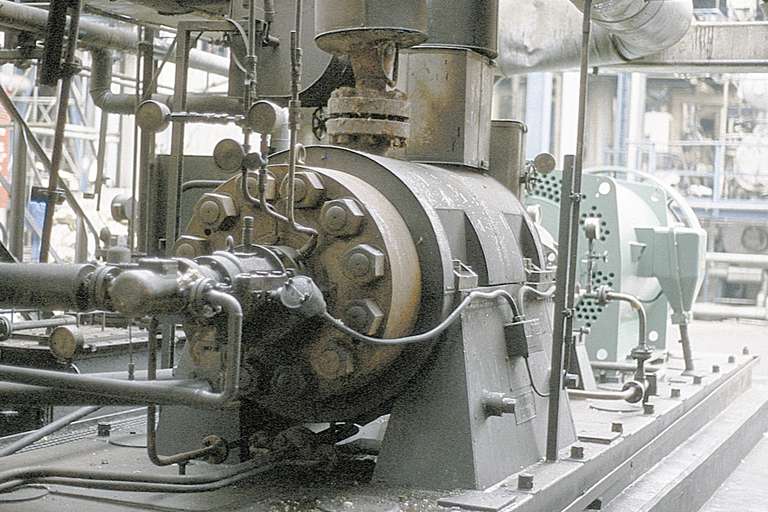

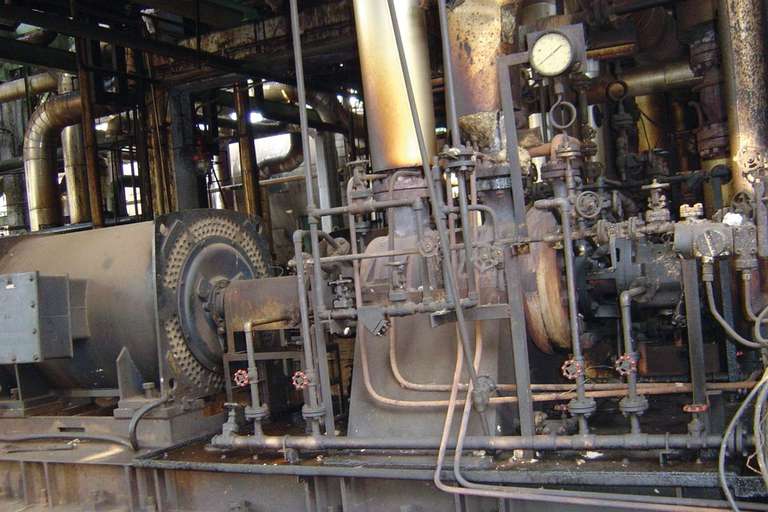

Demanding conditions - reliable solutions

For distillation, the crude oil is first heated to around 350 °C (662 °F) and then broken down into individual products. Substances with a boiling point above this temperature become gaseous and rise in the distillation column.

High temperatures and different compositions of crude oils - which can also be corrosive (hydrogen sulfide + sulfur) and abrasive - are some of the greatest challenges faced by the sealing technology used in refinery distillation facilities.

We guarantee reliable sealing of the complete process chain in distillation facilities with our proven H75 and LL9 pusher seal types, while the MFLWT and MBS metal bellows seals are preferred for particularly high temperatures. High quality sliding materials such as Buka 22 (a silicon carbide material) and structural materials from Inconel® are used for metal bellows.

We are happy to advise you

Would you like personal advice, do you have any questions or would you like to order directly? We look forward to supporting you.

Excellence in Practice

With our free e-mail newsletter „Excellence in Practice“, you will receive first-hand information about current products, services, references and worthwhile industry insights.