Service agreement for the newsprint production

The Palm Paper Ltd. paper mill produces newsprint for national and international newspapers. Production is based solely on waste paper pulp. A TotalSealCare service agreement having a duration of several years includes servicing of all installed mechanical seals for pulp pumps, mixers and various pressure screens. Additional contractually agreed services are on-site presence during start-ups, troubleshooting and providing seal-related schooling and training courses for plant personnel.

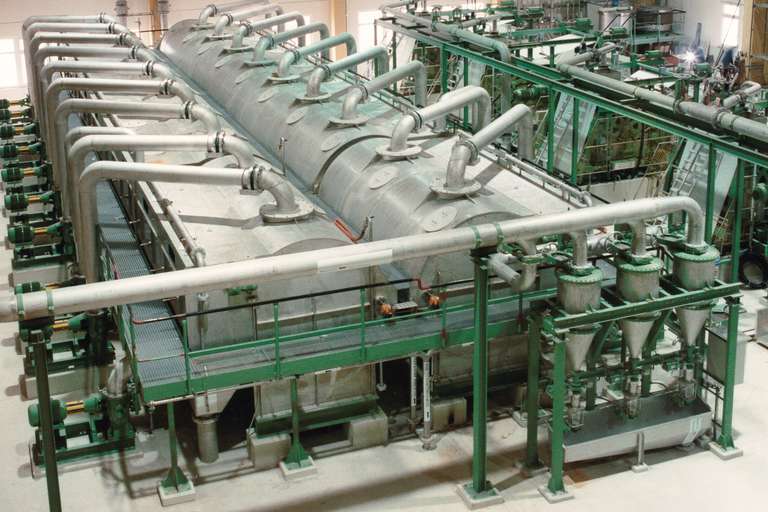

Shaft seal for waste paper treatment

In the waste paper treatment at Palm in Wörth, Germany, four TL200/TL300 type Metso Screens with LP-D-ST-D15/130-DE were retrofitted to non-flow operation and have been running in continuous operation (24 hrs./day) since 2004.

Medium: Pulp 3 % abs. dry and water, t = 50 °C (122 °F), p3 = 4 bar (58 PSI), n = 800 min-1.

Double cartridge seal for pressure sorter

At UPM Kymmene Shotton in England, nine Voith pressure screens in waste paper treatment are being used successfully with EagleBurgmann HR-D type double cartridge seals. Medium to be sealed: Pulp fibers 1.5 ... 4 % abs. dry and water, p = 8 bar (116 PSI), t = max. 40 °C (104 °F).

Compression packings for pump shafts

In Kartonsan, Turkey, numerous pumps for pulp treatment and in the de-inking system have been successfully equipped with EagleBurgmann Burasoft 6225-L type compression packings.

Shaft seal for slot sorters

At Stora Enso Maxau, Germany, Voith slot sorters in a waste paper treatment plant for the production of standard and upgraded newsprint paper are sealed with EagleBurgmann HR10 type seals (dead-end). Flushing with circuit water (return water) is used only when the medium has a too high solids content.

Face material combination SiC/SiC, shaft diameter d1 = 46 130 mm (1.81 5.12), p1 = 1 bar (15 PSI), t = 60 °C (140 °F), n = 980 min-1, medium: Paper pulp (0.2 ... 5 % abs. dry).