Mechanical seal LP-D for a pressure disk filter

EagleBurgmann convinced the persons responsible for the liquor line in a pulp mill to equip the shaft of the pressure disk filter with the practical and reliable mechanical seal LP-D, thereby increasing the MTBR to an extraordinarily long period of three years.

Operating conditions: p1 = 1.3 … 1.5 bar (18.8 PSI … 21.7 PSI), t = +85 °C … + 90 °C (+185 °F … + 194 °F), vg = <1 m/s (3,28 ft/s), n = 0.5 … 3 min-1, Medium: Lime milk mixture (white liquor and lime slurry)

Read on for the entire case study

Secure sealing of white water

HA211 type mechanical seals operate in the fiberization process of the mechanical pulp production at Nippon Paper in Japan to provide secure sealing of white water.

Operating conditions: p = 1 bar (15 PSI), t = 30 °C (86 °F), n = 1,450 min-1.

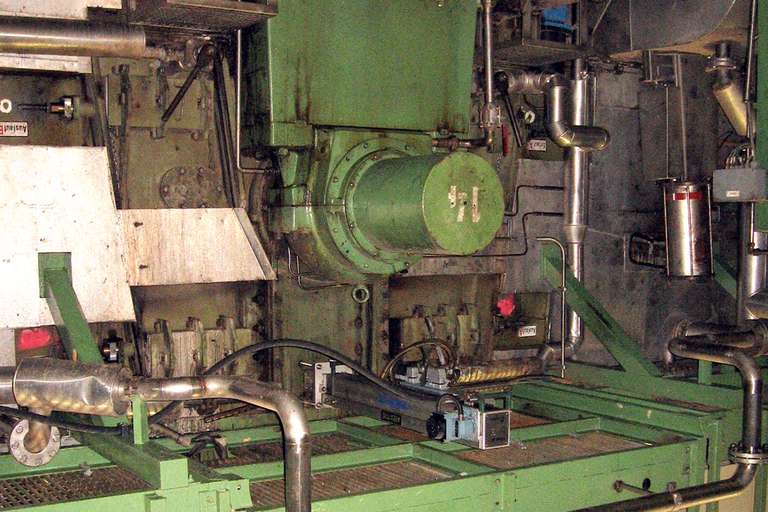

Mechanical seal for grindstone shaft

UPM Plattling/Germany uses Metso pressure grinders to fiberize wood. EagleBurgmann HSSHR8-D4/470-E1 type mechanical seals are used to seal off both sides of the high-consistency groundwood pulp at the grindstone shaft.

Operating conditions: p = 3 bar (44 PSI), t = 150 °C (302 °F), n = 350 min-1.

Mechanical seal for pressure grinder

EagleBurgmann M42S2/470-00 type mechanical seals operate successfully in several pressure grinders in the pulp mill at Stora Enso Publication Paper in the Maxau/Germany plant.

Espey shaft seal

A horizontally arranged machine shaft is sealed by an Espey E-WDKS205 type carbon floating ring seal at Norske Skog Saugbrugs in Norway.

Operating conditions: t = 40 °C ... 50 °C (104 °F ... 122 °F), n = 11 ... 15 min-1.

Injectable packing in Andritz refiners

EagleBurgmann Burajet SF6335 and Burajet 8032SCW type compression packings are installed in Andritz refiners as shaft seals at the Mexican paper factory Copamex Papelara de Chihuahua.

Operating conditions: p = max. 16 bar (232 PSI), t = 200 °C (392 °F).