Mechanical seal SHFVI for a boiler circulation pump

A boiler circulation pump in the coal-fired block of a power plant conveys very hot and pressurized water. Its seals must function properly up to 300 °C (572 °F) and at a pressure of up to 150 bar (2,175 PSI). The pump has no cooling jacket, which increased the risk of a thermosiphon effect. EagleBurgmann prevents the exchange of cold and warm water on the shaft by the mechanical seal SHFVI and the screw pump HPS.

Read on for the entire case study...

RoTechBooster for compressor seals

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system with RoTechBooster that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Read on for the entire case study...

Shaft seal for main cooling water pump

EagleBurgmann HGH210/225-E1 are installed in the main cooling water pump at the KNG power plant in Rostock.

Operating conditions: p = 2.25 bar (23.63 PSI), t = 25 °C (77 °F), n = 490 min-1, medium: brackish water with sand.

Packings for boiler control valves

Isartherm-Flex 6050/KIN compression packings are used to seal boiler control valves at Dubai Electricity and Water Authority in Saudi Arabia.

Operating conditions: p = 100 bar (1,450 PSI); t = 550 °C (1,022 °F).

Valve retrofit to TA-Luft

TotalSealCare On-site Service: during boiler maintenance at the RWE power plant in Frimmersdorf, Germany, EagleBurgmann performed a control valve retrofit. The valves have been equipped with a life loading system and made compliant according to the European IPPC directive (TA-Luft): p = 23 bar (344 PSI), t = 495 °C (923 °F), n = 8,200 min-1.

Espey shaft seal in a turbine

Hot steam has to be contained in a turbine at the Vapo Oy Pellet power station in Finland. An Espey WKA400 carbon floating ring seal with steam and condensate leakage drain is used in this application.

Operating conditions: p = 23 bar (344 PSI), t = 495 °C (923 °F), n = 8,200 min-1.

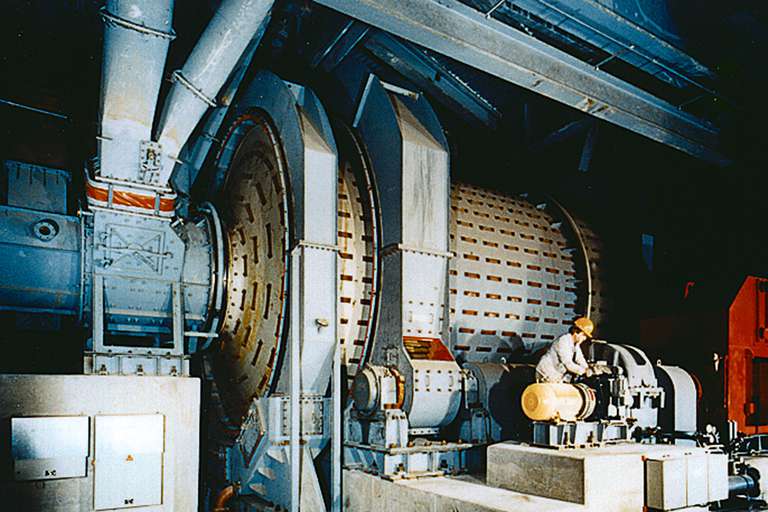

Espey shaft seal for coal mills

At the Dezhou Shandong Huaneng Power Development Co. Ltd. power plant in China, sealing air is used to contain hot exhaust air laden with coal dust in the neck of a coal mill. The ideal solution: An Espey WD200/500.

Operating conditions: p = 1.08 bar (15.66 PSI), t = 110 °C (230 °F), n = 15.8 min-1.

Expansion joints for flue gas ducts

Fluastal expansion joints (9 x 5 m) made of special fabric are installed in a flue gas duct at the EGAT Wang Noi power plant in Thailand.

Operating conditions: p = 0.074 bar (1.07 PSI); t = 580 °C (1,076 °F).

Shaft seal for feedwater pump

Buraflex 2000 HT compression packings are used to seal a feedwater pump at the cogeneration plant in Pforzheim, Germany.

Operating conditions: p = 72 bar (1,044 PSI), t = 180 °C (356 °F).

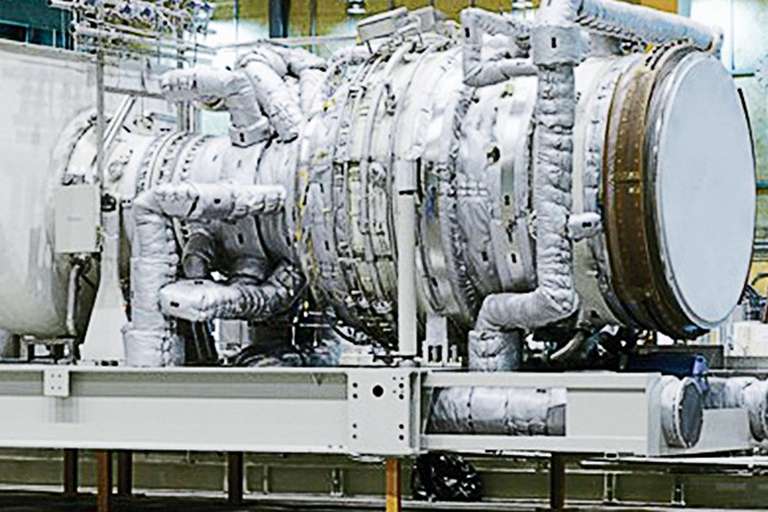

Expansion joint for gas turbine

A fabric expansion joint manufactured by EagleBurgmann Expansion Joints Solutions installed in a Siemens SGT 800 gas turbine.

Operating conditions: p = 9.8 ... 14 mbar (142 ... 203 PSI), t = 620 °C (1,148 °F), gas flow rate: 40 m/s, axial displacement 34 mm, lateral displacement +4 mm.

Compression packings for exhaust gas

At the PT.Ipmomi coal-fired power plant in Indonesia, sealing for high temperature exhaust gas which contains fly ash and steam is needed on a soot blower. Isartherm 6011A and Isartherm-Flex 6050 compression packings help to maintain safe and reliable operation.

Operating conditions: p = 40 bar (580 PSI); t = 400 °C (752 °F).

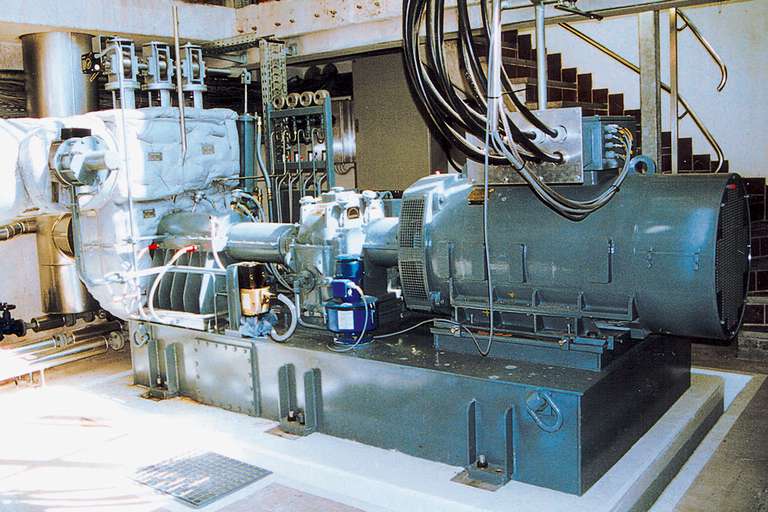

Shaft seal for KSB feed water pump

A SHV1/200-E1 mechanical seal is installed in a KSB CHTA140 feedwater pump at the ENBW power plant in Heilbronn, Germany.

Operating conditions: p = 30 bar (435 PSI); t = 180 °C (356 °F); n = 5,100 min-1.

Shaft seal for suspension pump

A suspension pump is used to circulate abrasive milk of lime at the RWE power plant in Frimmersdorf, Germany, sealed with an EagleBurgmann HR325/270-G11-E6 mechanical seal.

Operating conditions: p = 3 ... 4.5 bar (44 ... 65 PSI); t = 50 °C (122 °F); n = 890 min-1.

Expansion joint for air preheater

Expansion joints with specially shaped edges are installed in an air preheater at East Kentucky Power in the U.S.

Operating conditions: p = 0.07 ... 0.24 bar (1.02 ... 3.48 PSI), t = 34 ... 540 °C (640 °F ... 1,004 °F).

Shaft seal for boiler circulation pump

A boiler circulation pump is installed in the feedwater circuit at the municipal power plant in San Antonio, TX, USA. The pump shaft is sealed by two SHFV3/125-FTA mechanical seals.

Operating conditions: p = 170 bar (2,465 PSI); t = 340 °C (644 °F); n = 1,800 min-1.

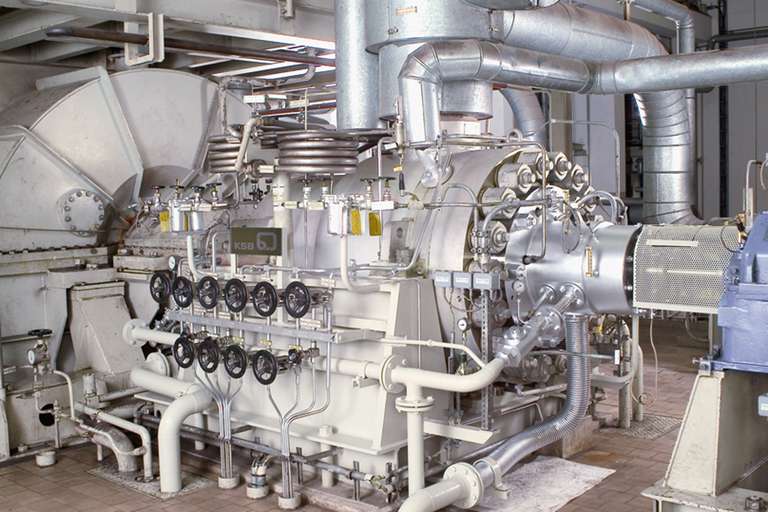

Seal and system for feedwater pump

The RWE power plant in Niederaussem, Germany uses a Weller pump in the feedwater circuit. A mechanical seal type SAPV1/138-E2 along with a SPF9025/A005-V1 seal supply system is applied.

Operating conditions: p = 20.2 ... 27.5 bar (293 ... 399 PSI); t = 177 °C ... 201 °C (351 °F ... 394 °F); n = 1,000 ... 5,100 min-1.

Shaft seal for boiler feedwater pump

A steam-driven Sulzer HTP500-505-5s is installed at the Waigaoqiao Phase III power plant in China. EagleBurgmann SAFV1/210-E1/-E2 mechanical seals are used for sealing the boiler feedwater.

Operating conditions: p = 33 bar (479 PSI), t = 180 °C (356 °F), n = 5,100 min-1.

Diamond-coated mechanical seals

EagleBurgmann DF-SAPI1/158 diamond-coated mechanical seals operate trouble-free in a boiler feed pump at a coal-fired power station in Hadong, South Korea.

Operating conditions: p = 23 bar (334 PSI); t = 173 °C (343 °F); n = 5.830 min-1.

Diamond-coated mechanical seals

The EagleBurgmann DF-SAFI4/188 diamond-coated mechanical seal runs in the boiler feed pump of the black coal power station in Voerde, Germany, to the complete satisfaction of the operator.

Operating conditions: p = 21 bar (305 PSI); t = 158 °C (316 °F); n = 5.100 min-1.

Semi-split shaft seal for main cooling water pumps

The power stations' main condenser is supplied with vast quantities of cooling water via two main cooling water pumps. Despite of the highly abrasive sand content of the pumped medium (Baltic sea water), the installed HGH run without any problems and was in operation for 12 years until the next sheduled pump oberhaul.