Situation

High costs for procurement, maintenance and warehousing, risk of assembly errors

Standard Cartex seal in all pumps of a pulp and paper mill reduces costs

High costs for procurement, maintenance and warehousing, risk of assembly errors

Limitation to a few standard seals for different pumps in the entire process chain

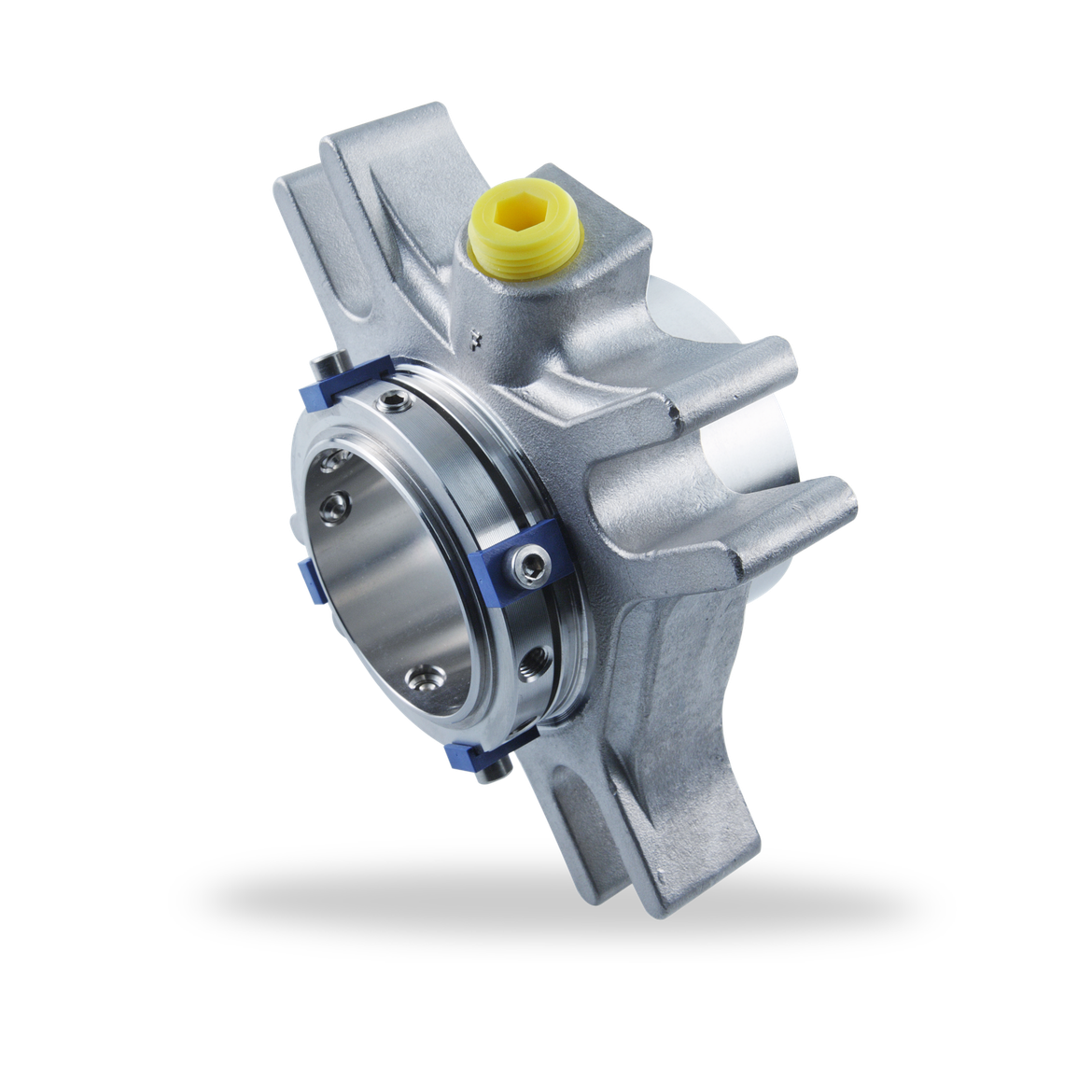

Cartridge seal Cartex-DN and Cartex-SN by EagleBurgmann

730 pumps in different designs, shafts with diameters from 33 to 100 mm, a hundred seal types with different material combinations, several suppliers - this was the situation a few years ago in a pulp and paper mill of a Swedish packaging manufacturer. Packaging cartons for the beverage and food industry and liner paper with a production capacity of 740,000 tons per year are produced in its factory.

The pumps are found throughout the entire process chain - from wood preparation to cooking, washing, bleaching and paper finishing. Mainly single-stage centrifugal pumps are used. Depending on the process stage, the seals on the pump shafts are exposed to abrasive wood fibers, wood particles, cellulose, aggressive chemical substances or water.

The many different seal types and the various material combinations caused a high expenditure for maintenance and warehousing. There was a permanent risk of incorrect material selection and of assembly errors. EagleBurgmann saw great potential for reducing costs for the paper manufacturer by switching to standardized seals. The seal specialist recommended that after an inventory and subsequent analysis of the data, the packaging manufacturer should standardize the seals which would greatly simplify procurement, warehousing, maintenance and assembly.

EagleBurgmann offered the packaging manufacturer a standardization package consisting of several elements. In addition to inventory and analysis of the resulting data, the package included services such as spare parts management, a multi-stage repair program, on-site services with installation and services such as the "Bad Actor program". Training courses for fitters and users completed the package.

The packaging manufacturer was open to the standardization approach and so EagleBurgmann went to work and determined which pump types were installed at which point in the process as a prerequisite for the later offer. Afterwards, the details of the individual pumps were discussed in order to later select suitable standard seals: What is the diameter of the shafts, what are the dimensions of the stuffing box chambers, how large are the bearings and which seals are fitted to the shafts? It was also necessary to check the operating conditions, media and supply systems in cooperation with the customer.

After all the data had been analyzed, the recommendation was to use seals from EagleBurgmann's Cartex-DN and Cartex-SN series. 23 instead of the previous hundred seal types would be sufficient for all pumps. The double seal Cartex-DN should be used for processes with chemical media, and the single seal Cartex-SN should be used for media with pulp and hot water. Since seal faces in one material combination per series are sufficient, this considerably reduces the risk for the customer of selecting the wrong material combination. The cost of repairs is reduced in the same way.

The standardization concept for repairs generally stipulates that the seals "rotate" from the paper mill to the EagleBurgmann service center and back. The repair program has three stages and regardless of which stage the customer chooses, the costs are defined from the outset and there is no need to prepare a quotation for each individual repair.

Standardized seals also simplify the work of the planning department. Because only Cartex seals are in operation, the technicians know exactly which spare parts will be required for the next revision of the plant. Likewise, matching the seals in operation with the seals registered in the IT system is also easier.

The seals at the packaging manufacturer’s paper mill are now being gradually replaced with Cartex seals. EagleBurgmann uses an adapter to mount the seals. This allows the sealing specialist to use the same seal to cover pumps with different stuffing boxes and housings. The adapter is mounted only once and does not need to be replaced during maintenance or repairs.

The advantage of the standardization concept is that the allocation of each seal to a specific pump is known in the plant. If errors accumulate, the cause can be determined precisely and quickly as part of the "Bad Actor program" and the error rectified. For another customer in the pulp and paper industry, EagleBurgmann increased the average service life of the seals to ten years with the help of the Bad Actor program.

In plants with many different seal types in operation, usually only one or two spare seals are on stock. The plant operator therefore depends on express delivery to receive new ones. Standardization facilitates increased availability by keeping more seals on stock.

The Swedish customer has initially opted for the complete standardization package. If he realizes over time that he would like to use fewer services, costs will only be incurred for the package contents used. EagleBurgmann’s standardization concept meets the individual needs of the customer.

A cost reduction in the medium term will be noticeable through:

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.