Situation

Continuous axial movements of the shaft and explosive atmosphere

Dry-running agitator seal SeccoMix R in paddle dryers

Continuous axial movements of the shaft and explosive atmosphere

Robust and easy to clean seal that doesn't require barrier fluid

Dry-running SeccoMix R agitator seals from EagleBurgmann

For some years now there has been a trend in the pharmaceutical industry to use gas-lubricated and dry running mechanical seals without barrier fluid to avoid contamination of the product wherever possible. For agitators with usually low speeds, dry-running mechanical seals have proven to be very reliable.

Also available now are specific hygienic designs which are easy to clean and sterilize, with materials which meet the requirements of the U.S. Food & Drug Administration (FDA) and the United States Pharmacopeia (USP), Class VI.

A global pharmaceutical company with headquarters in Switzerland took a leading role when they started the so-called "oil free" project several years ago. The objective was to convert liquid-lubricated mechanical seals to dry-running or non-contacting mechanical gas seals wherever possible. In most cases, the company decided to convert to dry-running mechanical seals because they were perceived to be more robust and service friendly than non-contacting mechanical gas seals.

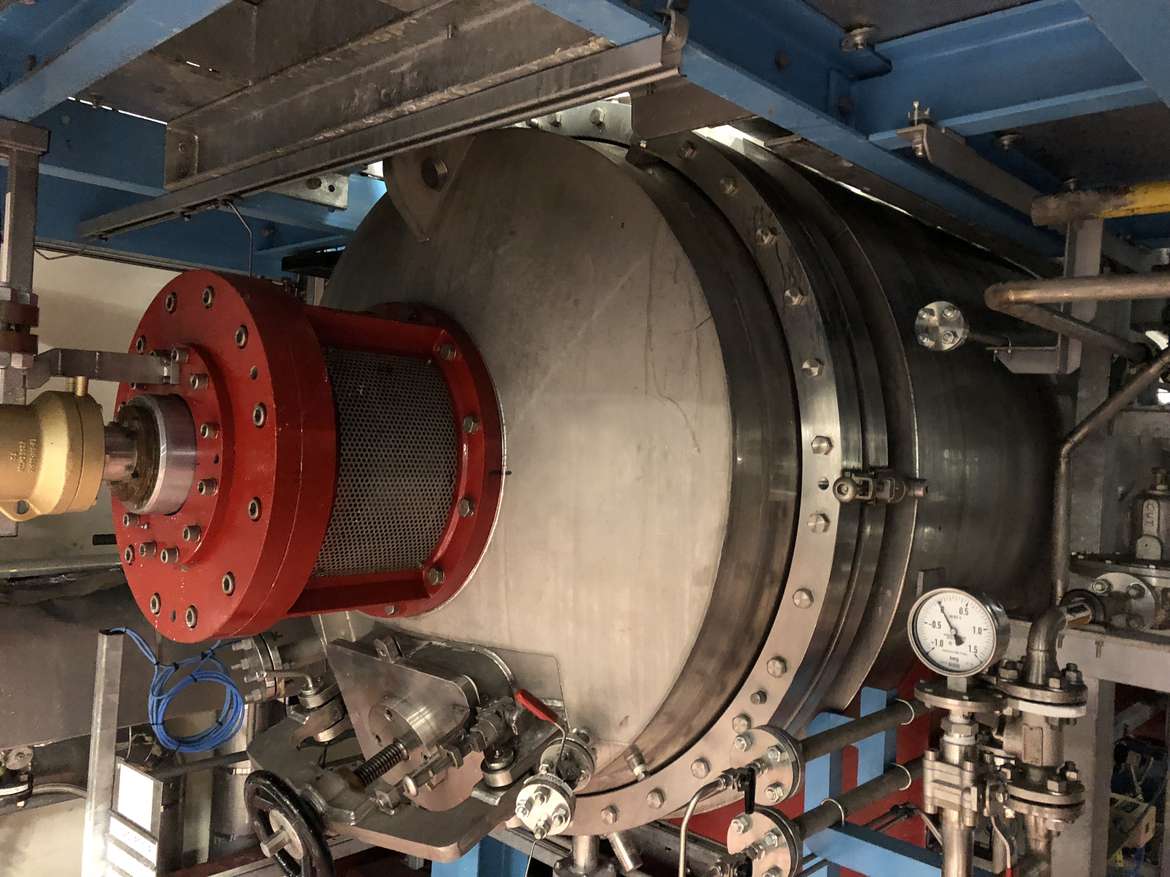

As an example, dry-running “SeccoMix R” mechanical seals have been successfully in operation in seven paddle dryers in a production plant in England for several years. In this plant, the company produces active pharmaceutical ingredients (APIs) for drugs by chemical synthesis in batch operation mode. The paddle dryers are used to separate the produced active substance from the solvent.

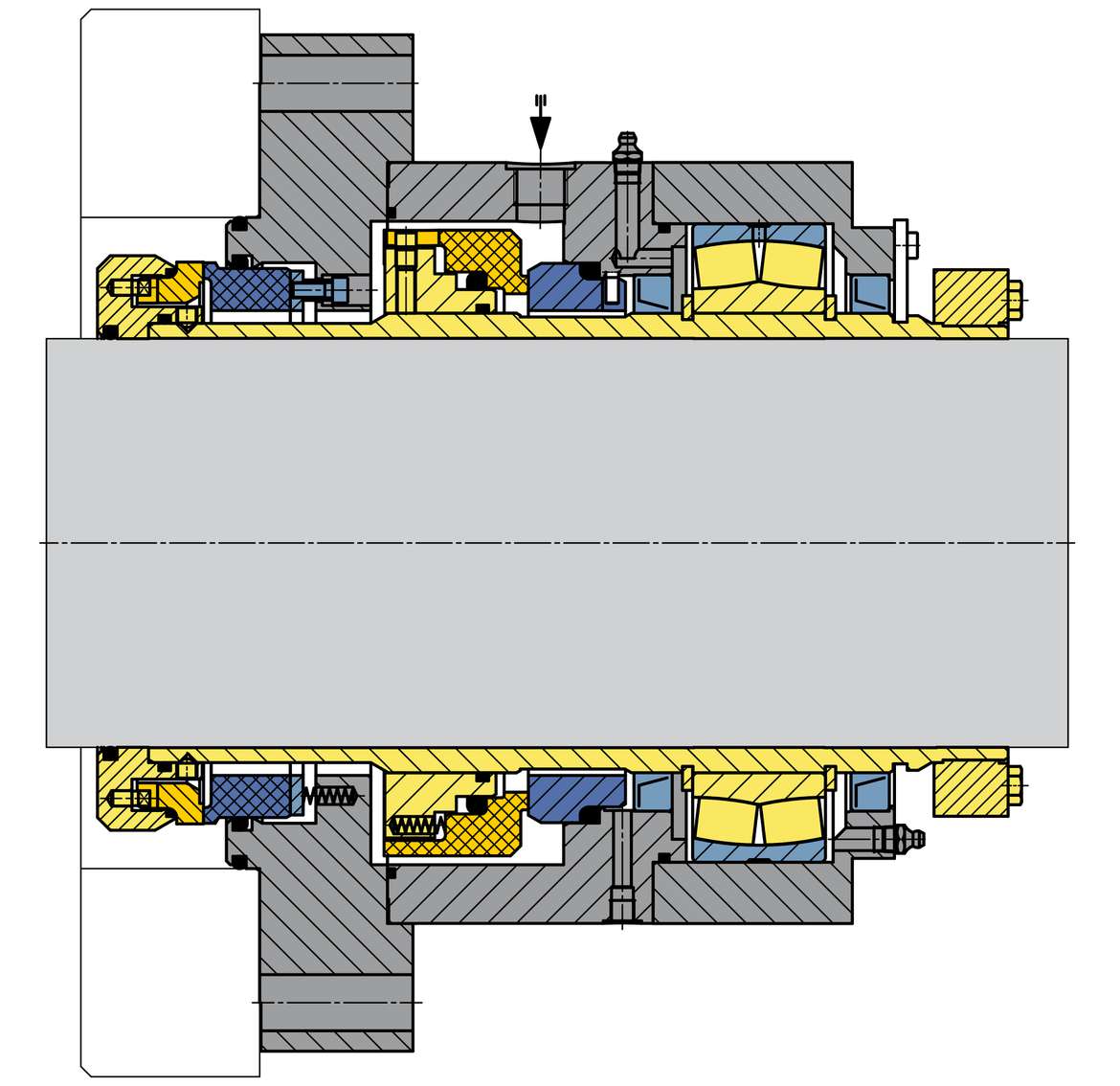

The rotating shaft of the horizontal dryers with bearings on both sides is equipped with mixing elements. Heating is provided via a double jacket and a hollow shaft. The dryers are operated with vacuum to atmospheric pressure and moderate temperatures between - 20 °C and + 90 °C (-4 °F … +194 °F). In case of cleaning or sterilization, higher temperatures of up to 160 °C can occur for a short time. Rotational speed is 20 min-1 and therefore very low. For a shaft diameter of 200 mm (7.87”), this means a sliding speed of 0.1 m/s (0.32 ft/s) for the mechanical seal. These operating conditions are typical of paddle dryers, but many of them are also operated under pressure or at higher temperatures.

In the first fit, the paddle dryers were equipped with liquid-lubricated “HSMR” seals from EagleBurgmann which were converted to dry-running SeccoMix R-seals in the course of the "oil free" project. Each dryer has a mechanical seal on the drive and non-drive end, initially with the same design at each end. However, it became evident that the axial movement of the shaft at the non-drive end, due to thermal expansion, was too large to be compensated by the seal itself.

Frequent axial movements due to the shaft length and numerous temperature changes also have to be compensated. The SeccoMix R at the non-drive end was therefore equipped with a fixed bearing and wipers. The bearing fixes the seal axially at the shaft sleeve of the mechanical seal, and the wipers allow relative movements between shaft and shaft sleeve. After this modification, all seals at the site in England will run with a service life of three years or more.

The SeccoMix R double seals are operated with a barrier gas of mostly nitrogen which prevents the product from leaking to the atmosphere. The process side of the mechanical seal protrudes into the vessel, i.e. the flow conditions are optimal for good cleaning properties. Attention was also given to a construction with little dead space and a hygienically flawless surface quality. All materials in contact with the product, such as sliding materials and secondary seals, are FDA approved. The bearing grease is approved in accordance with NSF H1 and therefore suitable for food and pharma applications.

Under the moderate operating conditions of this application, shedding and abrasion of the seal face material is extremely low, particularly with regard to the overall capacity of the vessel of about 3,000 l. Not all of the abraded material goes into the dryer because most of it remains inside the seal housing.

The solvents used in the production process at this English production site carry the risk of an explosive atmosphere, which means the requirements regarding explosion protection regulation and Directive 2014/34/EC must be considered. In the present case, the mechanical seal must be suitable for category 2 (zone 1) and temperature class T3. Category 2 means that an explosive atmosphere can occasionally occur at the seal during normal operation, and the temperature class is dependent on the medium properties. T3 means a maximum temperature of 200 °C (392 °F) for the surface exposed to the product. SeccoMix R seals can meet these demands without any difficulties. Even if temperature class T4 were required, which permits a maximum surface temperature of up to 135 °C (275 °F), it is possible to use SeccoMix R after checking the operating conditions.

The bottom line is that dry-running mechanical seals are a reliable alternative to liquid-lubricated seals, especially for moderate operating conditions. This often applies to agitators and other engineered equipment with agitators, filter dryers and nutsche filters. Pharmaceutical applications nowadays are increasingly accepting dry-running mechanical seals. The Swiss pharmaceutical company is very satisfied with the dry-running seals from EagleBurgmann.

Would you like to learn more about our range of products & services for the pharmaceutical industry?

Find our more here. Or feel free to contact us.

Dry-running agitator seal SeccoMix R in paddle dryers.

Mechanical seals for agitators, mixers, dryers, kneaders and other special machines. The true all-rounders when it comes to aggressive, sticky or viscous media or when solids content is high.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.