Situation

- High level of maintenance, risk of product contamination

Situation

Challenge

Solution

Vistin Pharma is a Norwegian pharmaceutical company headquartered in Oslo. The company produces metformin hydrochloride as an active pharmaceutical ingredient (API) and as direct compressible granulate. The mixing of the product is a critical part of the production process. The agitator shafts must be properly sealed to ensure a process flow without interruption.

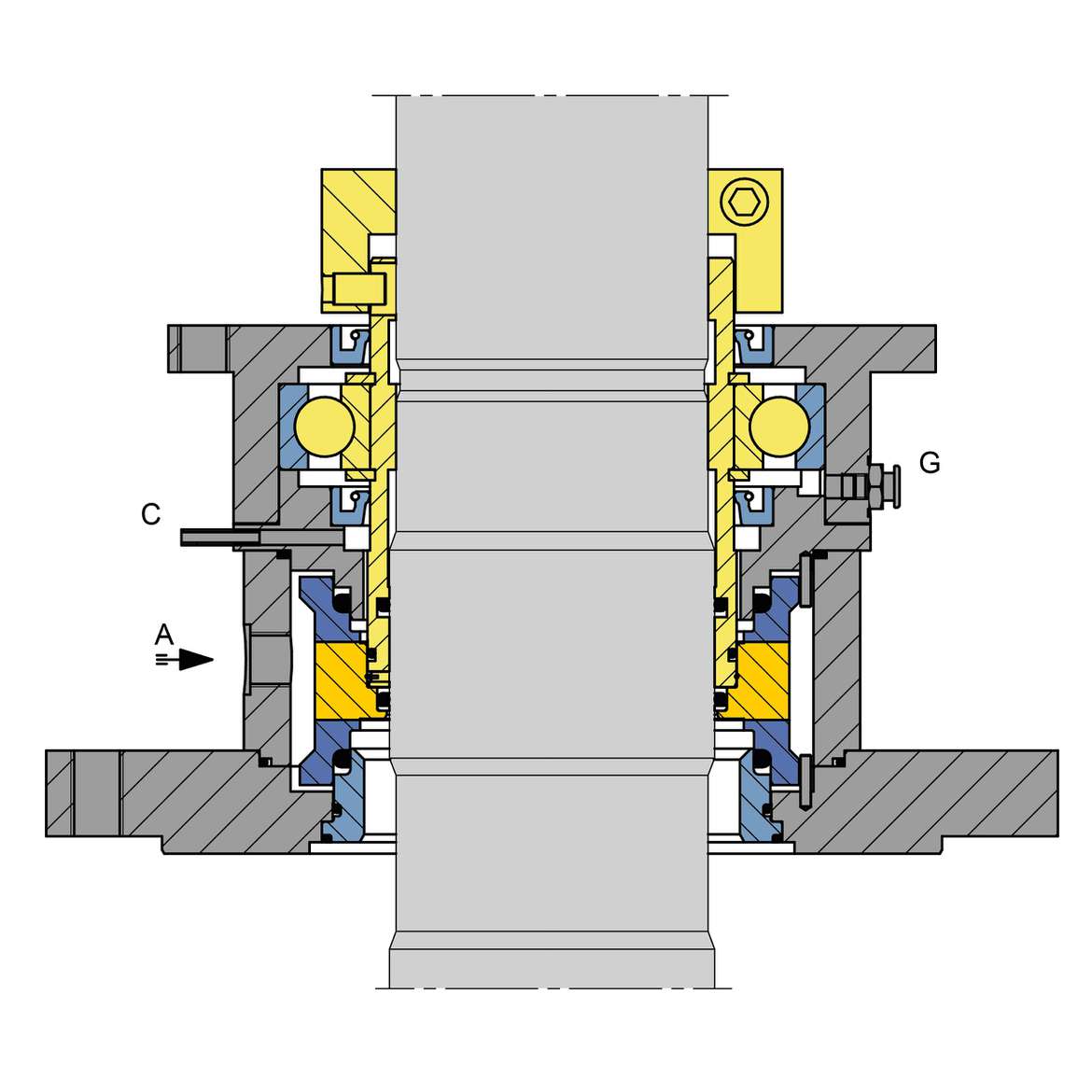

At the manufacturing facility in Sannidal, Norway, Vistin Pharma uses glass-lined vessels with a capacity ranging from 12,5 m³ to 35 m³ for dissolving, mixing, reaction, separation and distillation of the solvents. Since 2014, some shafts of the top-mounted agitators have been equipped with AGSZ double seals from EagleBurgmann.

Product quality and operating cost largely depend on smooth-running processes. Until the retrofit, Vistin Pharma used oil-lubricated seals from a competitor. These seals not only required a high level of maintenance on a regular basis, but also the risk of contaminating the product with barrier fluid and wear particles. That is why Vistin Pharma wanted to stop using oil as barrier fluid. The manufacturer decided to order the gas-lubricated AGSZ seals from EagleBurgmann.

Because these seals are pressurized, they prevent contamination of the product from outside and contamination of the atmosphere with the product from inside. The seals also make sure the required pressure in the vessel can be maintained.

The seals operate without contact, hence there is no abrasion. Geometry and treatment of the sliding surfaces ensure a continuous and consistent stable layer of gas. Due to extremely precisely manufactured grooves, seat and seal face reliably lift off even at low speeds. As the seal is operated at a pressure higher than the pressure inside the vessel, the product cannot penetrate the sealing gap. At Vistin Pharma the AGSZ seals are supplied with nitrogen from the network in the production facility. A gas supply system from EagleBurgmann regulates the required gas flow. It is specifically designed for dry running and gas-lubricated mechanical seals.

The clamping ring torque transmission allows the shaft to axially move ±2 mm (0,07"), while the integrated bearing protects the seal from large radial forces. Even if the vessel with a capacity of 30 m3 is fully loaded, the user can rely on the safe operation of the seal.

Because the seal is pressurized, it cannot be contaminated by the product and it is not necessary to clean the seal. To prevent damage while cleaning the vessel with hot steam, the pressure inside the seal must be higher than the pressure of the steam.

Seal faces and seats made of silicon carbide and O-rings with product contact comply with FDA regulation. The seal also complies with the ATEX directive, Zone 0. These characteristics highlight the compliance of the seals with strict international standards and regulations.

So far, the seals at Vistin Pharma are proving to be very stable during operation and have been running smoothly. This has reduced maintenance expenditures. In addition, the seals support an optimized energy management in the production process due to their non-contacting operation. No contact means no friction in the seals faces. Therefore, no heat at the seal must be dissipated.

A scheduled downtime in early 2019 was used to check one of the seals. As the AGSZ is a ready-to-fit and factory-tested unit, it could have been repaired easily but its condition turned out to be as good as new. The seal only required normal maintenance to ensure it continues to function.

Our range of products & services for the pharma industry

EagleBurgmann provides the pharmaceutical industry with extensive support in the field of sealing technology. Find out more here. Or feel free to contact us today.

Retrofit of agitators with AGSZ seals

AGS agitator seals – For maximum product purity. Designed for reactors, mixers, dryers and special machine.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.